Stockport Aqua Blasting

Service in association with Ric Wood Motorsport & CNC Heads

Stockport Aqua Blasting Services

We offer aqua/ vapour blasting services specialising in automotive & motorsport component cleaning & restoration. We are based near Stockport/ Manchester but also offer our services to the rest of the UK.

To receive a quote, please fill out the form at the bottom of the page with the requested information; prices will vary due to size, shape and condition of the item.

We work in association with Ric Wood Motorsport & CNC Heads, two well established and highly regarded businesses in the Automotive and Motorsport sectors, with clients from around the UK, Europe and the rest of the world.

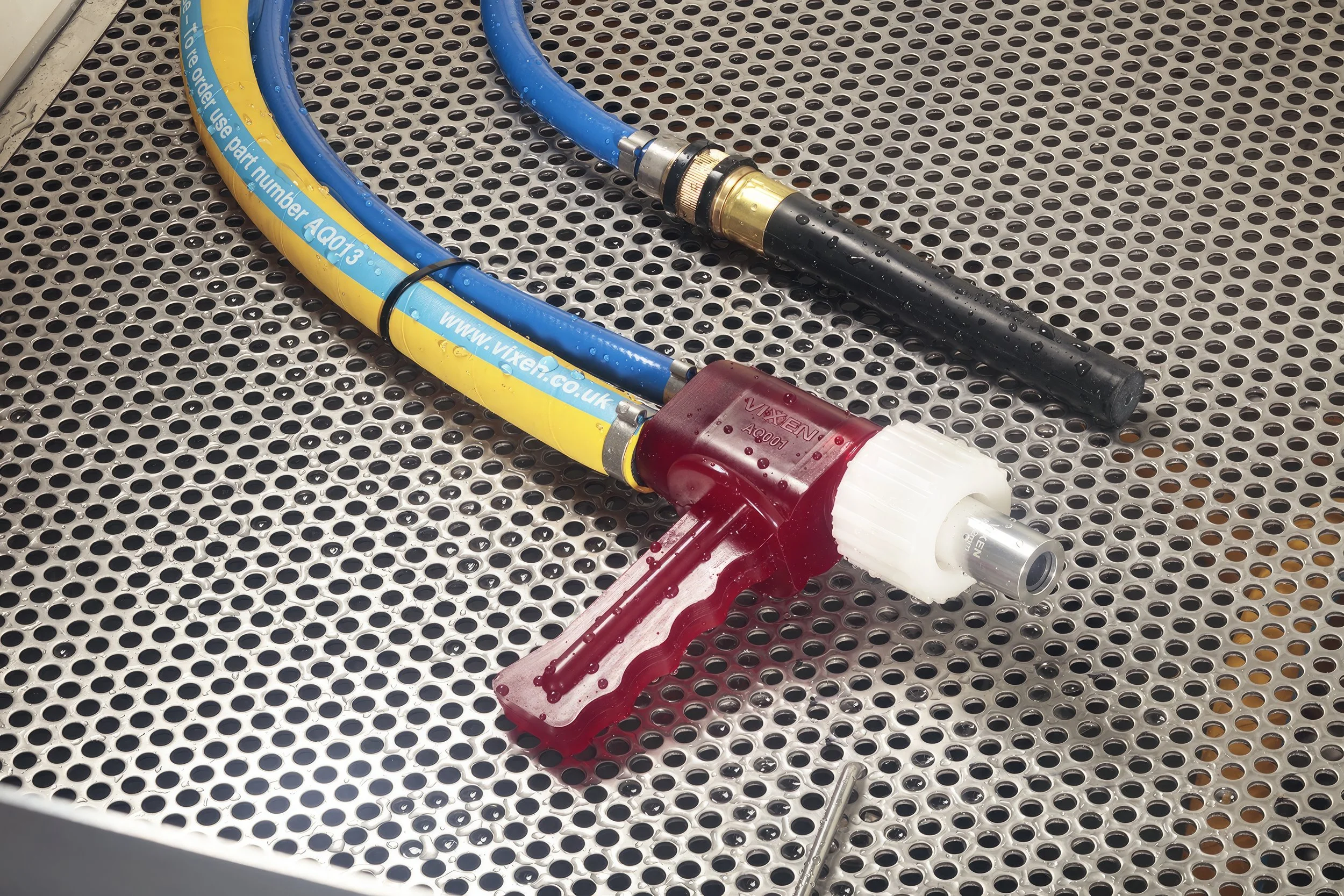

The Aquablast® 1215 is a large wet blasting cabinet and is suitable for small, medium or large sized components. Vixen is a highly regarded company, they are a leading manufacturer and supplier of quality cleaning equipment, with a well established customer base including Triumph Motorcycles, RedBull F1, Kawasaki and Jaguar Land Rover

This cabinet cleans by flow, thereby eliminating impact, resulting in a 'soft' finish with the water acting as a lubricant. Media impregnation is avoided, and the life of the blast media is also extended.

The water/media slurry is contained within the wet blasting cabinet sump.

Delivery of the slurry to the manual blast nozzle is via a glandless polyurethane pump and associated hoses located inside the wet blasting machine.

Compressed air is added at the blast nozzle to accelerate the slurry and provide the cleaning effect.

After contact with the component the slurry, then drains back into the sump creating a re-circulating system.

Fine broken-down media and other contaminants are fed via an overflow to a sedimentation filter located at the rear of the wet blasting machine.

The benefits to Aqua blasting

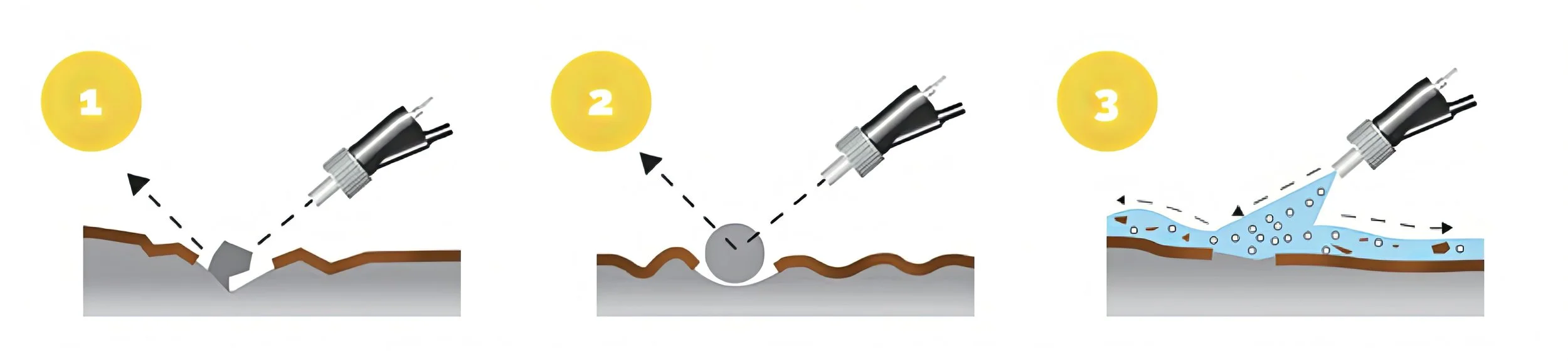

The illustrations show the different natures of grit, bead, and wet blasting. The aggressiveness of dry grit and bead blasting is shown in the first two illustrations which demonstrate the severe 90° ricochet that occurs when using these methods.

The third illustration shows the gentler, but just as effective, vapor blasting method. The ricochet of media is reduced due to the cushioning from the water; the angle of the media is changed producing a lapping effect travelling across the surface, giving an even satin/polished finish.

Vapor blasting is the go-to choice for the engineering and aerospace industries. Vapor blasting can efficiently remove oxidation, old paint, carbon deposits, and other contaminants from objects and machinery.

In the aerospace industry, vapor blasting is one of the safest ways to prepare a surface. The final finish is consistent and smoother than other blasting techniques.

The most apparent difference between vapor blasting and things like sand blasting is the use of water. While both blasting processes are similar, vapor blasting requires one extra step of adding water. The water, however, reduces dust and results in a more even finish.

Aqua Blasting is suitable for a range of metals including Aluminium, Bronze, Magnesium, Titanium, Brass, Copper, Steel & Iron.

See how it works…

We may ask for photos of the parts following your enquiry but these will be exchanged over email rather than through this page.

Please fill out the form below to request a quote.